1360 Series

2 way solenoid valves for corrosive fluids

Main Characteristic

1/4″ to 1/2″ Connection

Normally Closed

Teflon, PVC or Acrylic Bodyl

Viton Seats

Direct Action up to 30psi

Shielded core. Solenoid parts totally isolated from the fluid.

Shape A DIN 43650 connection encapsulated coil.

IP65 and NEMA 4 protection.

Absence of galvanic electrolysis.

No contamination of the fluid handled.

Applications:

Corrosive fluid handling

Options:

•Energized coil indicator light.

•Explosion and weather proof coils

and housings.

Options:

Explosion Proof

Weather Proof

Please select Body material by selecting the TAB

| Options | Prefix | Suffix | Examples |

|---|---|---|---|

| Explosion & Weather Proof Coil | ZC | ZC2026BA222T | |

| BSP Connections | no |

2026BA222 |

|

| Energized Coil Indicator Light | please ask |

INSTALLATION

The valve outlet pressure could be higher than the inlet pressure, but in this case there is no guaranty that the fluid would no leak.

We recommend installing a strainer of <= 100 micron upstream to the valve.

| Voltage | Watts | Resistance (ohms) | Amps Inrush | Amps Holding |

|---|---|---|---|---|

| 12V/DC | 6 | 0.5 | 0.5 | |

| 24V/DC | 6 | 0.25 | 0.25 | |

| 110V/DC | 6 | 0.05 | 0.05 | |

| 24V/AC60 | 6 | o.54 | 0.33 | |

| 120V/AC60 | 6 | 0.11 | 0.06 | |

| 240V/AC60 | 6 | 0.05 | 0.03 |

Other voltages available upon request.

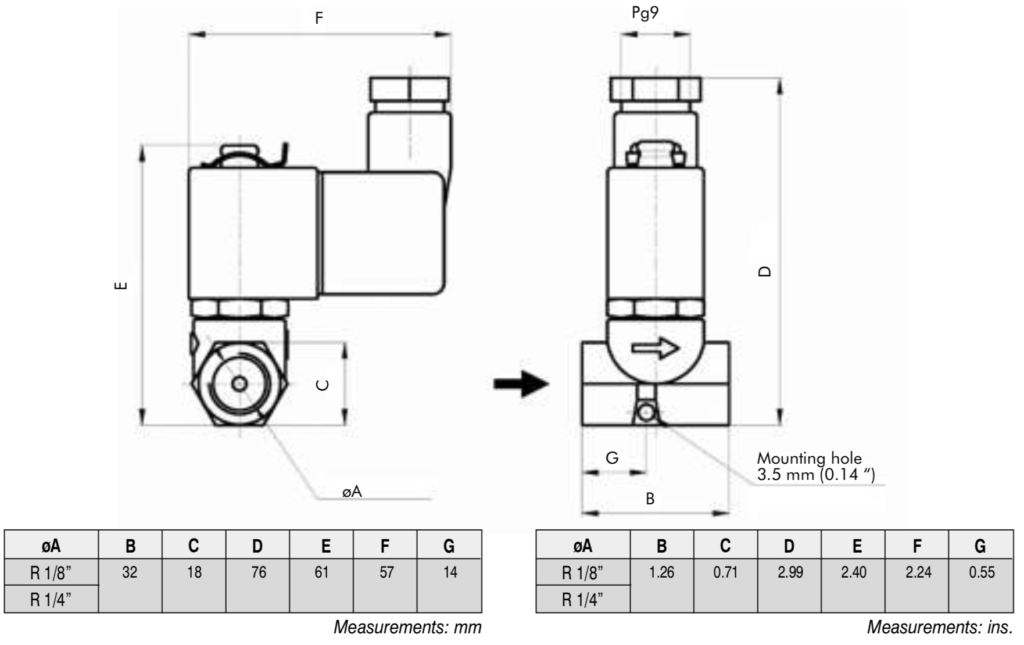

GENERAL DIMENSIONS