UC Series

2 Way Solenoid Valves – for Cryogenic Service and liquid CO2

Main Characteristic

1314, 1327 and 1390 Series Solenoid Valves are

specially modified to control cryogenic flow.

Cryogenic fluids include liquid nitrogen, liquid argon, liquid oxygen,

and liquid CO2.

Normally Closed and Normally Open

Direct Acting. No minimum differential pressure to operate

or Pilot Operated with low min pressure to open.

Brass or Stainless Steel Body

1/8″ to 2″ NPT (BSP upon request)

Coil: Encapsulated Class H 356F with DIN Connectors or flying leads (upon request)

Applications:

Cryogenic fluids -200C to 50C (-328F to 122F)

Liquid CO2: -60C to 50C (-76F to 122F)

Options:

Explosion Proof

Weather Proof

| Pipe size | Material | Name | Summary | Price | Buy | Buy | price_hsort |

|---|---|---|---|---|---|---|---|

| 1/2" | Bronze | 1314BST04UCT | 2 Way Normally Closed 1/2″ NPT Brass Solenoid Valve w/Teflon Seats (Max Fluid Temp 122F) – 0.75 ins orifice – Cv: 5.27 – Direct Action – Min/Max. Diff. Pressure 0/105psi | $0.00 |

Select options

This product has multiple variants. The options may be chosen on the product page

| 0 | |

| 3/4" | Bronze | 1314BST06UCT | 2 Way Normally Closed 3/4″ NPT Brass Solenoid Valve w/Teflon Seats (Max Fluid Temp 122F) – 0.75 ins orifice – Cv: 7.02 – Direct Action – Min/Max. Diff. Pressure 0/105psi | $0.00 |

Select options

This product has multiple variants. The options may be chosen on the product page

| 0 | |

| 1" | Bronze | 1314BST08UCT | 2 Way Normally Closed 1″ NPT Brass Solenoid Valve w/Teflon Seats (Max Fluid Temp 122F) – 1.02 ins orifice – Cv: 11.7 – Direct Action – Min/Max. Diff. Pressure 0/105psi | $0.00 |

Select options

This product has multiple variants. The options may be chosen on the product page

| 0 | |

| 1 1/2" | Bronze | 1314BST12UCT | 2 Way Normally Closed 1.1/2″ NPT Brass Solenoid Valve w/Teflon Seats (Max Fluid Temp 122F) – 1.26 ins orifice – Cv: 17.6 – Direct Action – Min/Max. Diff. Pressure 0/105psi | $0.00 |

Select options

This product has multiple variants. The options may be chosen on the product page

| 0 | |

| 2" | Bronze | 1314BST16UCT | 2 Way Normally Closed 2″ NPT Brass Solenoid Valve w/Teflon Seats (Max Fluid Temp 122F) – 1.5 ins orifice – Cv: 26.9 – Direct Action – Min/Max. Diff. Pressure 0/105psi | $0.00 |

Select options

This product has multiple variants. The options may be chosen on the product page

| 0 | |

| 1/4" | Brass | 1327BT121INAUCT | 2 Way Normally Open 1/8″ NPT Brass Solenoid Valve w/Teflon Seats (Max Fluid Temp 122F) – 0.05 ins orifice – Cv: 0.06 – Direct Action – Min/Max. Diff. Pressure 0/750psi | $0.00 |

Select options

This product has multiple variants. The options may be chosen on the product page

| 0 | |

| 1/4" | Brass | 1327BT121UCT | 2 Way Normally Closed 1/8″ NPT Brass Solenoid Valve w/Teflon Seats (Max Fluid Temp 122F) – 0.05 ins orifice – Cv: 0.06 – Direct Action – Min/Max. Diff. Pressure 0/1500psi | $0.00 |

Select options

This product has multiple variants. The options may be chosen on the product page

| 0 | |

| 1/4" | Brass | 1327BT171INAUCT | 2 Way Normally Open 1/8″ NPT Brass Solenoid Valve w/Teflon Seats (Max Fluid Temp 122F) – 0.07 ins orifice – Cv: 0.11 – Direct Action – Min/Max. Diff. Pressure 0/300psi | $0.00 |

Select options

This product has multiple variants. The options may be chosen on the product page

| 0 | |

| 1/4" | Brass | 1327BT171UCT | 2 Way Normally Closed 1/8″ NPT Brass Solenoid Valve w/Teflon Seats (Max Fluid Temp 122F) – 0.07 ins orifice – Cv: 0.11 – Direct Action – Min/Max. Diff. Pressure 0/525psi | $0.00 |

Select options

This product has multiple variants. The options may be chosen on the product page

| 0 | |

| 1/4" | Brass | 1327BT221INAUCT | 2 Way Normally Open 1/8″ NPT Brass Solenoid Valve w/Teflon Seats (Max Fluid Temp 122F) – 0.09 ins orifice – Cv: 0.15 – Direct Action – Min/Max. Diff. Pressure 0/180psi | $0.00 |

Select options

This product has multiple variants. The options may be chosen on the product page

| 0 | |

| 1/4" | Brass | 1327BT221UCT | 2 Way Normally Closed 1/8″ NPT Brass Solenoid Valve w/Teflon Seats (Max Fluid Temp 122F) – 0.09 ins orifice – Cv: 0.15 – Direct Action – Min/Max. Diff. Pressure 0/300psi | $0.00 |

Select options

This product has multiple variants. The options may be chosen on the product page

| 0 | |

| 1/4" | Brass | 1327BT301INAUCT | 2 Way Normally Open 1/8″ NPT Brass Solenoid Valve w/Teflon Seats (Max Fluid Temp 122F) – 0.12 ins orifice – Cv: 0.3 – Direct Action – Min/Max. Diff. Pressure 0/150psi | $0.00 |

Select options

This product has multiple variants. The options may be chosen on the product page

| 0 | |

| 1/4" | Brass | 1327BT301UCT | 2 Way Normally Closed 1/8″ NPT Brass Solenoid Valve w/Teflon Seats (Max Fluid Temp 122F) – 0.12 ins orifice – Cv: 0.3 – Direct Action – Min/Max. Diff. Pressure 0/150psi | $0.00 |

Select options

This product has multiple variants. The options may be chosen on the product page

| 0 | |

| 1/4" | Brass | 1327BT302INAUCT | 2 Way Normally Open 1/4″ NPT Brass Solenoid Valve w/Teflon Seats (Max Fluid Temp 122F) – 0.12 ins orifice – Cv: 0.3 – Direct Action – Min/Max. Diff. Pressure 0/150psi | $0.00 |

Select options

This product has multiple variants. The options may be chosen on the product page

| 0 | |

| 1/4" | Brass | 1327BT302UCT | 2 Way Normally Closed 1/4″ NPT Brass Solenoid Valve w/Teflon Seats (Max Fluid Temp 122F) – 0.12 ins orifice – Cv: 0.3042 – Direct Action – Min/Max. Diff. Pressure 0/150psi | $129.99 – $145.59 |

Select options

This product has multiple variants. The options may be chosen on the product page

| 129.99 | |

| 1/4" | Brass | 1327BT402INAUCT | 2 Way Normally Open 1/4″ NPT Brass Solenoid Valve w/Teflon Seats (Max Fluid Temp 122F) – 0.16 ins orifice – Cv: 0.5 – Direct Action – Min/Max. Diff. Pressure 0/150psi | $0.00 |

Select options

This product has multiple variants. The options may be chosen on the product page

| 0 | |

| 1/4" | Brass | 1327BT402UCT | 2 Way Normally Closed 1/4″ NPT Brass Solenoid Valve w/Teflon Seats (Max Fluid Temp 122F) – 0.16 ins orifice – Cv: 0.5031 – Direct Action – Min/Max. Diff. Pressure 0/75psi | $129.99 – $145.59 |

Select options

This product has multiple variants. The options may be chosen on the product page

| 129.99 | |

| 1/4" | Brass | 1390BBT2INAUCT | 2 Way Normally Open 1/4″ NPT Brass Solenoid Valve w/Teflon Seats (Max Fluid Temp 122F) – 0.24 ins orifice – Cv: 0.94 – Pilot Operated Action – Min/Max. Diff. Pressure 1.5/150psi | $0.00 |

Select options

This product has multiple variants. The options may be chosen on the product page

| 0 | |

| 1/4" | Brass | 1390BBT2UCT | 2 Way Normally Closed 1/4″ NPT Brass Solenoid Valve w/Teflon Seats (Max Fluid Temp 122F) – 0.24 ins orifice – Cv: 0.936 – Pilot Operated Action – Min/Max. Diff. Pressure 1.5/225psi | $0.00 |

Select options

This product has multiple variants. The options may be chosen on the product page

| 0 | |

| 3/8" | Brass | 1390BBT3INAUCT | 2 Way Normally Open 3/8″ NPT Brass Solenoid Valve w/Teflon Seats (Max Fluid Temp 122F) – 0.35 ins orifice – Cv: 1.87 – Pilot Operated Action – Min/Max. Diff. Pressure 1.5/150psi | $0.00 |

Select options

This product has multiple variants. The options may be chosen on the product page

| 0 | |

| 3/8" | Brass | 1390BBT3UCT | 2 Way Normally Closed 3/8″ NPT Brass Solenoid Valve w/Teflon Seats (Max Fluid Temp 122F) – 0.35 ins orifice – Cv: 1.87 – Pilot Operated Action – Min/Max. Diff. Pressure 1.5/225psi | $0.00 |

Select options

This product has multiple variants. The options may be chosen on the product page

| 0 | |

| 1/2" | Brass | 1390BBT4UCT | 2 Way Normally Closed 1/2″ NPT Brass Solenoid Valve w/Teflon Seats (Max Fluid Temp 122F) – 0.47 ins orifice – Cv: 2.75 – Pilot Operated Action – Min/Max. Diff. Pressure 1.5/225psi | $0.00 |

Select options

This product has multiple variants. The options may be chosen on the product page

| 0 | |

| 1/2" | Brass | 1390BT4INAUCT | 2 Way Normally Open 1/2″ NPT Brass Solenoid Valve w/Teflon Seats (Max Fluid Temp 122F) – 0.47 ins orifice – Cv: 2.75 – Pilot Operated Action – Min/Max. Diff. Pressure 1.5/150psi | $0.00 |

Select options

This product has multiple variants. The options may be chosen on the product page

| 0 |

| Options | Prefix | Suffix | Examples |

|---|---|---|---|

| Weather Proof Coil | YC | YC1390BBT04UCT | |

| Explosion & Weather Proof Coil | ZC | ZC1390BBT04UCT | |

| BSP Connections | no |

1390BBT04UC |

INSTALLATION

1390 and 1314 ONLY install on a horizontal pipe with the coil upright.

1327 The preferred installation position is on a horizontal pipe with the coil upright, however you can install the valve in any position.

We recommend installing a strainer of <= 100 micron upstream to the valve.

The valve inlet pressure must always be greater than the outlet pressure.

| Voltage | Watts | Resistance (ohms) | Amps Inrush | Amps Holding |

|---|---|---|---|---|

| 12V/DC | 19 | 7.3 | 1.6 | 1.6 |

| 24V/DC | 19 | 27 | 0.8 | 0.8 |

| 110V/DC | 19 | 0.578 | 0.17 | 0.17 |

| 24V/AC60 | 13 | 4 | 1.9 | 1.1 |

| 120V/AC60 | 13 | 92 | 0.3 | 0.2 |

| 240V/AC60 | 13 | 0.38 | 0.2 | 0.1 |

Other voltages available upon request.

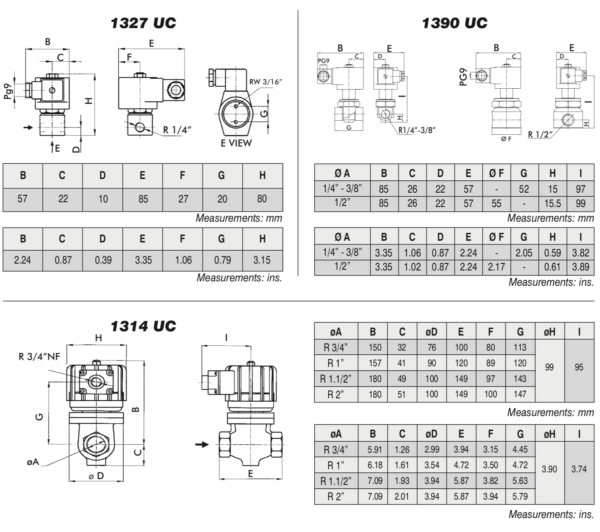

GENERAL DIMENSIONS